The Lion Foundry

About the Lion Foundry

This online exhibition features a small selection of the Lion Foundry drawings, photographs and objects held by EDLC Archives and Local Studies, and the Auld Kirk Museum. The Archives collections includes the Lion Foundry business records, drawings, photographs, and trade catalogues. The Auld Kirk Museum has a permanent exhibition of Lion Foundry artefacts and also holds a large collection of the patterns used in the moulding process. Contact us to find out more.

|

In 1880 an iron foundry was established on the north bank of the Forth & Clyde Canal at Kirkintilloch by the firm of Jackson, Brown & Hudson. The site was also adjacent to the Campsie Branch Railway, and was chosen with a view to receiving the delivery of raw materials by canal vessel and sending out finished products by rail. The firm was renamed “The Lion Foundry Company” in 1885 and became a limited liability company in 1893. |

|

|

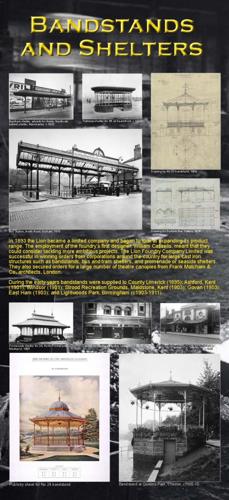

Towards the end of the 19th century, the Lion Foundry range branched out from gates, railings, rainwater castings and other comparatively mundane products, into the field of constructional ironwork – elaborate bandstands, shelters, shopping arcades, verandahs and other such structures.

|

|

|

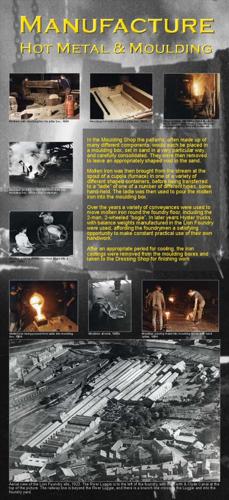

In the Moulding Shop, the patterns, often made up of many different components, would each be placed in a moulding box, set in sand in a very particular way, and carefully consolidated. They were then removed to leave an appropriately shaped void in the sand. |

|

|

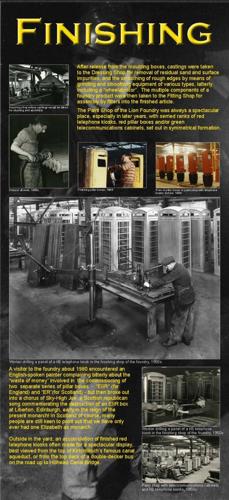

After release from the moulding boxes, castings were taken to the Dressing Shop for removal of residual sand and surface impurities, and the smoothing of rough edges by means of grinding and smoothing equipment of various types, latterly including a “wheelabrator”. The multiple components of a foundry product were then taken to the Fitting Shop for assembly by fitters into the finished article. |

|

|

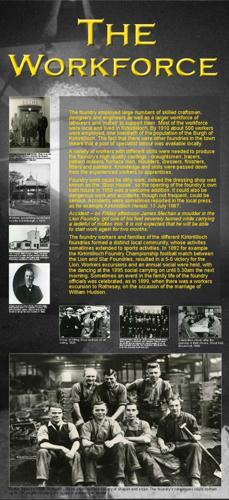

The foundry employed large numbers of skilled craftsmen, designers and engineers as well as a larger workforce of labourers and 'mates' to support them. Most of the workforce were local and lived in Kirkintilloch. By 1910 about 500 workers were employed, one twentieth of the population of the Burgh of Kirkintilloch. The fact that there were other foundries in the town meant that a pool of specialist labour was available locally. |

|

|

The opening of the foundry coincided with the mushroom growth of communities like Lenzie and Bearsden, where many large villas were built with extensive ornamentation in cast iron, including gates, railings, finials and weather vanes. Sadly, many of the local garden gates and railings were removed for scrap during World War Two, but a great deal of ornamental ironwork survives at roof level on the villas of East Dunbartonshire. |

|

|

In 1893 the Lion became a limited company and began to look at expanding its product range. The employment of the foundry’s first designer, William Cassells, meant that they could consider more ambitious projects. The Lion Foundry Company Limited was successful in winning orders from corporations around the country for large cast iron structures such as bandstands, bus and tram shelters, and promenade or seaside shelters. |

|

|

The period 1900-1914 saw the heyday of the Lion’s ornamental cast iron work. The foundry was involved in large constructional ironwork projects in cities all over the UK, from Glasgow and Edinburgh to Manchester, London, Birmingham and Portsmouth. With the outbreak of war in 1914, the firm returned to producing more utilitarian castings. It also manufactured bombs, a special cupola being installed for this purpose. |

|

|

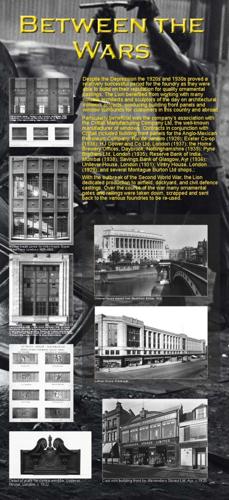

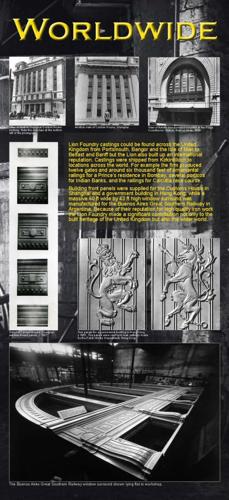

Despite the Depression, the 1920s and 1930s proved a relatively successful period for the foundry as they were able to build on their reputation for quality ornamental castings. The Lion benefited from working with many notable architects and sculptors of the day on architectural ironwork projects, producing building front panels and window surrounds for customers in this country and abroad. |

|

|

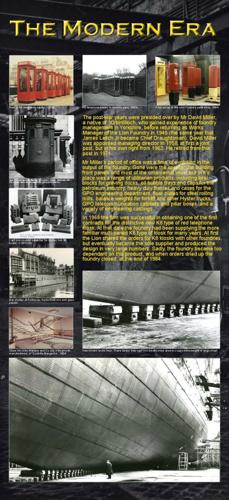

The post-war years were a time of evolution in the output of the foundry. Gone were the spectacular building front panels and most of the ornamental work, but in its place was a range of utilitarian products, including GPO telecommunication cabinets and pillar boxes, a variety of engineering castings and the distinctive new K8 type of red telephone kiosk. |

|

|

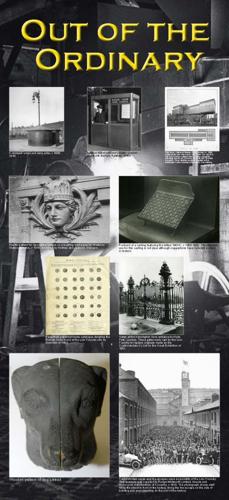

This panel shows some of the more unusual patterns and castings produced by the Lion Foundry. It also features an unusual advertising photograph for fire escape stairs - staff fill the street in front of the factory, line the fire escape on the side of building and even stand on the roof of the factory. |

|

|

Castings were shipped from Kirkintilloch to locations across the world. The firm produced twelve gates and around six thousand feet of ornamental railings for a Prince’s residence in Bombay, several porticos for Indian banks, and the railings for Calcutta race course. |

|

Documents

-

Lion Foundry - Introduction

-

Lion Foundry - Design

-

Lion Foundry - Manufacture

-

Lion Foundry - Finishing

-

Lion Foundry - Workforce

-

Lion Foundry - Early Years

-

Lion Foundry - Bandstands And Shelters

-

Lion Foundry - 20th Century

-

Lion Foundry - Between Wars

-

Lion Foundry - Modern Era

-

Lion Foundry - Out of the Ordinary

-

Lion Foundry - Worldwide